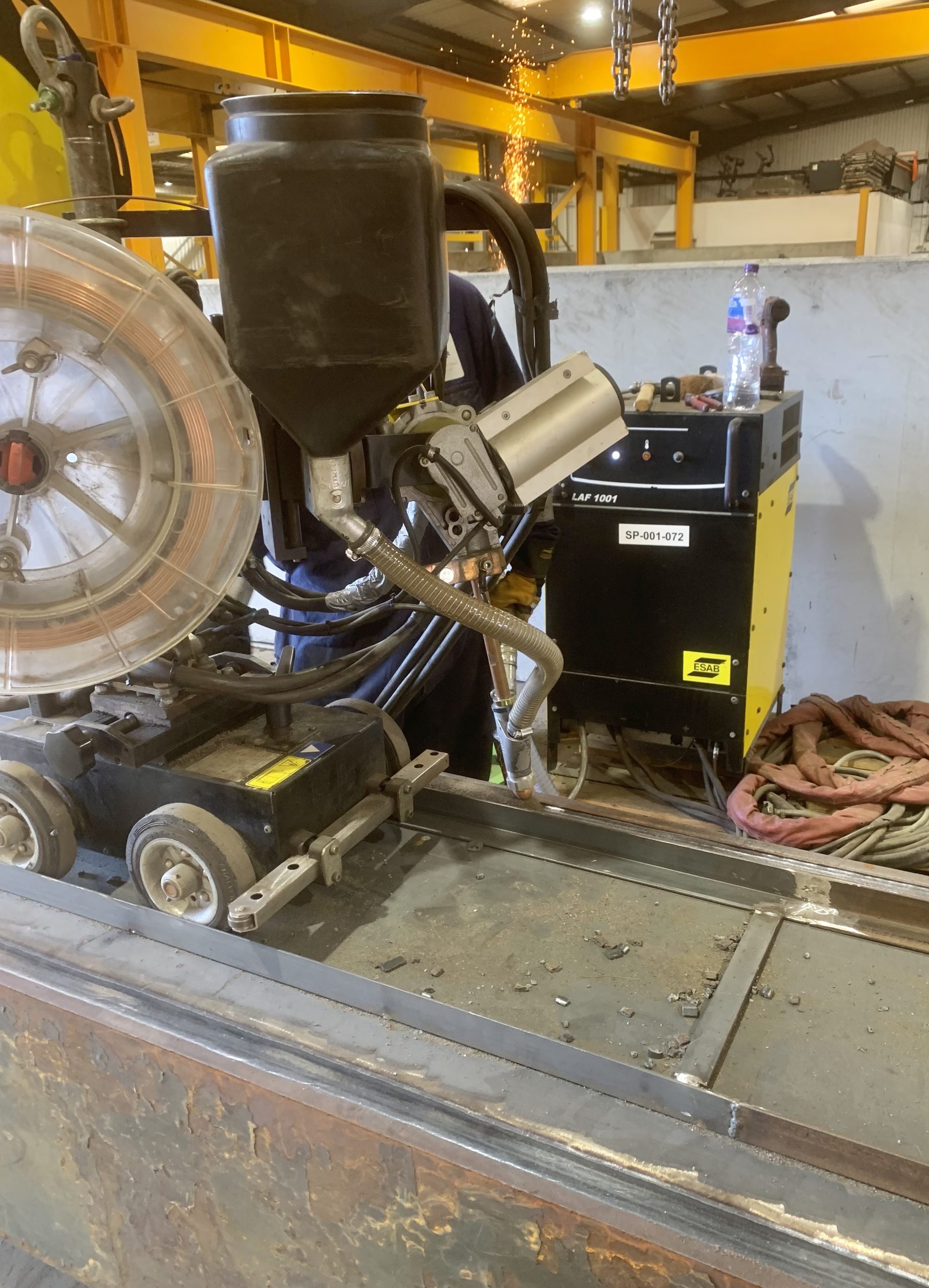

800amp ESAB LAF 1001 A2 PEK 4-wheel 25mtr submerged arc welder tractor for hire

In Stock - Hire Now! ✓

Download Spec Sheet (pdf)In stock for sale and available to hire we have the UK’s largest fleet of submerged arc welder tractors, with multiple LAF 1001 A2 PEK in stock.

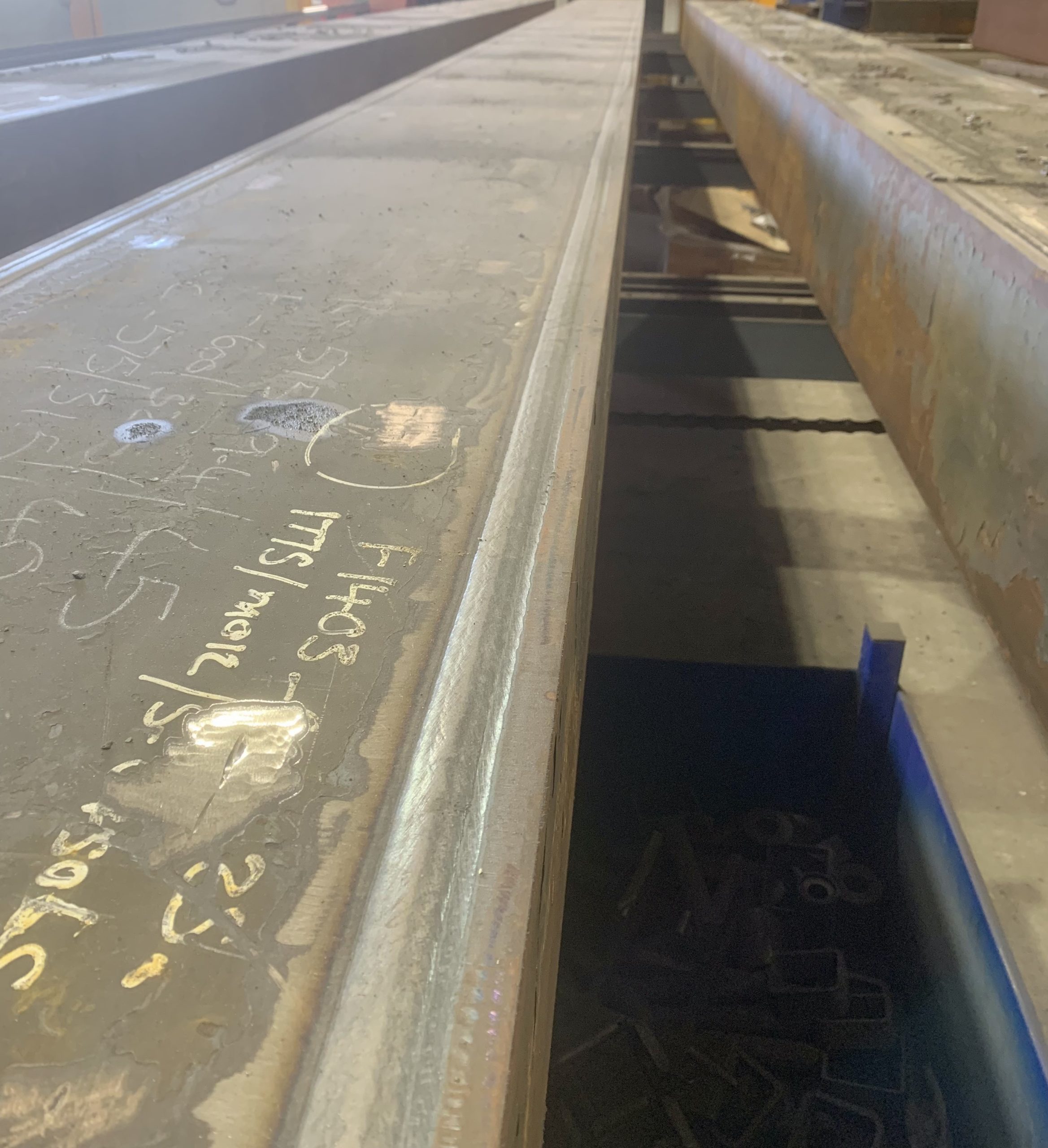

A few snaps of some of our hire plant ESAB LAF 1001 power sources c/w A2 PEK 4-wheel tractors (25mtr / 50mtr interconnection cable) submerged arc welders packages. These beastly machines have been laying down welds 24/7 on night shift for some time, without missing a beat. The guys have produced stunning runs 💥, that have passed inspection ðŸ§

The heavy bridge beams being welded had 2 ESAB sub arc welder power sources positioned in the middle of the beams, to enable the tractor unit interlink cable, to reach both ends. These were setup using ESAB 3.2mm wire and flux consumables, to achieve the required yield and tensile strength. The A2 tractors holding the weld tip, ran in opposite directions to each other, only passing once during the weld runs, keeping the interpass temperature down. This vastly sped the job up, with perfect results 🌉